Building A Stroker Info

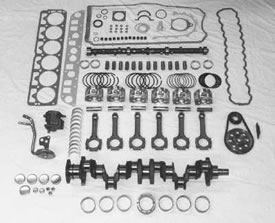

There's no replacement for displacement, so if you want even more torque, you need a bigger engine.

The 4.0L engine has a 3.411" stroke, 3.875" bore, 6 cylinders, and a displacement of 241.5ci (3956cc). You can increase the displacement of your 4.0L engine by installing a stroker kit. At the heart of the kit is the 3.895" stroke crankshaft that was used in the AMC/Jeep 258ci (4.2L) I6 engine.

On an engine with the stock 3.875" bore, the stroker crank increases displacement to 276ci (4517cc or 4.5L). Add 30 thousandths or 60 thousandths overbored pistons, and displacement is increased to 280ci (4587cc or 4.6L) and 284ci (4657cc or 4.7L) respectively.

If you're feeling really brave, you can overbore your engine to 4.00" and use custom forged pistons. The block must be sonic-tested to ensure that there's adequate cylinder wall thickness before overboring this far, though. Displacement with the 3.895" stroker crank is increased to 294ci (4812cc or 4.8L). The next step up the ladder includes an offset-ground 3.98" stroker crank that increases displacement to 300.1ci (4917cc or 4.9L). The ultimate stroker includes an offset-ground 4.06" stroker crank producing a displacement of 306.1ci (5016cc or 5.0L).

Here's some information on how you can build a stroker engine and the kits available. Budget stroker build-ups

I built the world's first "square" Jeep I-6 stroker engine with a bore and stroke of 3.895". It's a slight variant of the 4.6L low-buck stroker option 1 shown below.

I transformed a junkyard 4.0L short block plus a pile of parts into a rip-snorting torque monster with a displacement of 4563cc (4.6L), hence I entitled my stroker story "From Junker to Stroker".

My stroker engine's producing a calculated 265hp @ 4900rpm and 325lbft @ 3500rpm. At least 278lbft (1.0lbft/ci) is available from 1500-5000rpm, and over 300lbft is on tap from 2000-4500rpm. The difference in performance over the old modified 4.0 is very noticeable, particularly from 1500-4000rpm where I need it most. Performance-wise, this stroker engine has hit the bullseye!

Accurate Power stroker kit

Limeyjeeper built the 4.0L engine from his '99 WJ into a 4.6L stroker engine using this kit. It produced 210.5hp @ 4800rpm and 262.4lbft @ 3800rpm on the chassis dyno. Assuming a 20% drivetrain loss (RWD auto.), that's 263hp and 328lbft at the flywheel. Here's the link to Limeyjeeper's stroker story.

http://www.printroom.com/ViewAlbum.asp?userid=Lancia1&album_id=48070

Specs are the same as the medium-buck stroker shown below except for 0.030" overbore, Ford Motorsport 24lb/hr injectors, stock intake, and 62mm TB.

Accurate Power ceased trading in April 2005.

Hesco stroker kit

Available for all Jeeps in .030 or .060 oversize. Click on the image to the right.

A Hesco 4.7 stroker dyno'ed 267hp @ 4700rpm and 332lbft @ 3400rpm at the flywheel. The specs of that engine are in this Yahoo Stroker Group message.

Another Hesco built 4.6 stroker did even better on the engine dyno, producing 269hp @ 4800rpm and 340lbft @ 2500rpm.

Other stroker kits

Other stroker kits worth mentioning are supplied by Speedomotive and by StrokerKits.com You can also get a complete 4.6L stroker longblock engine from Golen Engine Service or Custom Design Performance

Accurate Power, Clifford Performance, and Jakes Racing Engines no longer supply stroker kits.

Injector sizing

Stroker engines require oversize injectors to provide adequate fuel flow rates and prevent pinging due to lean air/fuel mixtures.

To calculate optimum injector size, use the following formula:

Injector flow rate (lb/hr) = [Expected HP x 0.5 (BSFC)] / [no. of cylinders x 0.8 (injector duty cycle)]

The actual injector flow rate from each injector depends on the fuel pressure (FP) in the injector rail. Most injectors have rated flows at 43.5psi fuel pressure. The actual flow rate from each injector is:

Actual injector flow rate = Rated injector flow rate at 43.5psi x square root of (FP/43.5)

Adjustable fuel pressure regulator

Fine tune your engine's fuel curve with a Hesco adjustable fuel pressure regulator (FPR).

The fuel pressure can be adjusted to provide the optimum air/fuel ratio. Part no. for the '87-'90 FPR is HES8790FR Part no. for the '91-'95 FPR is HES9195FR

There is no adjustable FPR available for '96 and later engines.

Camshaft

Stroker engines need a longer duration camshaft (than stock) to maximise horsepower and torque.

The aim is to produce maximum torque over as wide an rpm range as possible. Stroker engines built with a compression ratio (CR) of about 9.5:1 will derive maximum benefit from these camshafts:

Crane #753905 204/216 degree cam CompCams #68-231-4 206/214 degree cam

A stroker built to a CR of 8.8:1 that'll run with 87 octane fuel will benefit from a shorter duration dual-pattern cam for more low rev torque:

Crane #750501 192/204 degree cam CompCams #68-115-4 192/200 degree cam

Long rods vs. short rods

If the Jeep 4.2L 5.875" rods and stock Jeep 4.0L pistons are used, the pistons will be 0.008" further down the bore at TDC than those in the stock Jeep 4.0L engine. The deck clearance is thus increased to 0.030" and the quench height is increased to 0.081". The resultant CR is 9.7:1 with stock bore pistons and 9.9:1 with 0.060" overbore pistons. If the block is decked 0.010" to return the quench height to stock, the combustion volume is reduced by 2.0ml and the CR is increased to 9.9:1 and 10.1:1 respectively. Premium fuel will be required to prevent detonation.

If the stock Jeep 4.0L 6.125" rods are used, expensive custom forged pistons with a shorter pin height than stock (1.380") are required to achieve zero deck clearance. Using longer rods does enable you to choose pistons with a larger dish volume than stock. These reduce the CR and allow the use of low octane fuel without detonation. You can also use a shorter duration camshaft for increased low-rev torque, and select the head gasket thickness required to achieve the desired 0.040"-0.060" quench height.

If you use the shorter Jeep 4.2L rods with cheaper cast aluminium or hypereutectic pistons, the quench height can be reduced by milling the block deck and installing a thinner head gasket. The CR can be reduced by increasing the combustion chamber volume and the piston dish volume.

- For each 0.010" milled from the block deck (or taken from head gasket thickness) to reduce quench height, the combustion volume decreases by ~2.0ml and the CR increases by ~0.2*.

Stroker engine math

Here are some formulae, and how they apply to the stock Jeep 4.0L engine:

1. Deck height = Rod length + stroke/2 + piston pin height + deck clearance

9.453" = 6.125" + 1.705" + 1.601" + 0.022"

2. Combustion volume = Combustion chamber volume + head gasket volume + deck clearance volume + piston dish volume

84.6cc = 56.7cc + 10.5cc + 4.3cc + 13.1cc

3. Compression ratio (CR) = Cylinder volume/combustion volume + 1.0

CR = 660/84.6 + 1.0 = 7.80 + 1.0 = 8.80

4. Quench height = Deck clearance + compressed head gasket thickness

0.073" = 0.022" + 0.051"

Stroker combinations

I've outlined ten stroker combinations below based on budget and desired horsepower levels. To get maximum benefit from the stroker engine you need a free-flow intake with Powerstack or K&N cone filter, 62mm bored HO throttle body, header, high-flow cat, performance muffler and 2.5" exhaust piping.

4.5L "Poor man's" simple stroker

~ Jeep 4.2L 3.895" stroke crank ~ Jeep 4.2L 5.875" rods ~ Speed Pro 677P standard bore pistons ~ 9.05:1 CR ~ Stock 4.0 HO camshaft ~ Stock HO cylinder head ~ Stock 0.051" head gasket ~ 0.097" quench height ~ 2.25" exhaust ~ Ford 24lb/hr injectors with stock 39psi FPR for '87-'95 engines, stock injectors with stock 49psi FPR for '96 and later engines 226hp @ 4600rpm, 304lbft @ 2000rpm

4.6L Low-buck, low CR "rockcrawler"

~ Jeep 4.2L 3.895" stroke crank ~ Jeep 4.2L 5.875" rods ~ Keith-Black Silvolite UEM-2229 +0.030" bore pistons ~ Increase piston dish volume to 30cc 8.8:1 CR ~ Crane #750501 192/204 degree camshaft ~ Ported HO 1.91"/1.50" cylinder head ~ Mill block deck 0.035" ~ Mopar Performance 0.043" head gasket ~ 0.058" quench height ~ 2.25" exhaust ~ Ford 24lb/hr injectors with stock 39psi FPR for '87-'95 engines, stock injectors with stock 49psi FPR for '96 and later engines ~ 231hp @ 4400rpm, 327lbft @ 2000rpm

4.5L Low-buck simple stroker

~ Jeep 4.2L 3.895" stroke crank

~ Jeep 4.2L 5.875" rods

~ Jeep 4.0L 3.875" standard bore pistons

9.7:1 CR

~ CompCams #68-231-4 206/214 degree camshaft

~ Ported HO 1.91"/1.50" cylinder head

~ Stock 0.051" head gasket

~ 0.081" quench height

~ Ford 24lb/hr injectors with adjustable FPR or MAP adjuster for '87-'95 engines, Ford 24lb/hr injectors with stock 49psi FPR for '96 and later engines

~ 260hp @ 4850rpm, 321lbft @ 3500rpm

4.6L Low-buck stroker

Option 1: Same as above except:

~ Speed Pro H825CP +0.030" bore pistons

~ 9.6:1 CR

~ Mopar Performance 0.043" head gasket

~ 0.082" quench height*

~ 260hp @ 4800rpm, 324lbft @ 3500rpm

Option 2: Same as "rockcrawler" except:

~ Piston dish volume 22cc

~ 9.5:1 CR

~ Crane #753905 204/216 degree camshaft

~ 2.5" exhaust

~ Ford 24lb/hr injectors with adjustable FPR or MAP adjuster for '87-'95 engines, Ford 24lb/hr injectors with stock 49psi FPR for '96 and later engines

~ 256hp @ 4750rpm, 324lbft @ 3500rpm

4.7L medium-buck stroker

~ Jeep 4.2L 3.895" stroke crank ~ Jeep 4.0L 6.125" rods ~ Custom +0.060" bore pistons with 1.38" pin height & 25cc dish ~ 9.6:1 CR ~ Crane #753905 204/216 degree camshaft ~ Ported big valve 2.02"/1.60" cylinder head ~ Mopar Performance 0.043" head gasket ~ 0.043" quench height ~ Flometrics F&B 68mm billet TB ~ Accel 26lb/hr injectors with adjustable FPR or MAP adjuster for '87-'95 engines, Accel 26lb/hr injectors with stock 49psi FPR for '96 and later engines. ~ 270hp @ 4800rpm, 335lbft @ 3400rpm

4.8L medium-buck stroker

Option 1: Same as above except: ~ Custom 4.0" bore pistons with 1.38" pin height & 24cc dish ~ 10.0:1 CR ~ CompCams #68-235-4 210/218 degree camshaft ~ 284hp @ 4900rpm, 345lbft @ 3600rpm

Option 2: Same as Option 1 except: ~ Jeep 4.2L 5.875" rods bushed for 0.912" floating pin ~ Small Block Ford UEM-KB364 hypereutectic pistons ~ Mill block deck 0.015" ~ 0.051" quench height

4.9L high-buck stroker

~ 3.98" offset-ground stroker crank

~ Jeep 4.2L 5.875" rods

~ Small Block Chevy UEM-KB142 hypereutectic pistons

~ 10.5:1 CR

~ Crane #753941 216/228 degree camshaft

~ Ported big valve 2.02"/1.60" cylinder head

~ Mill block deck 0.015"

~ Mopar Performance 0.043" head gasket

~ 0.055" quench height

~ Flometrics F&B 68mm billet TB

~ 3.0" exhaust system

~ Ford 30lb/hr injectors with adjustable FPR or MAP adjuster for '87-'95 engines, Ford 30lb/hr injectors with stock 49psi FPR for '96 and later engines.

~ Custom PCM programming

~ 299hp @ 5000rpm, 353lbft @ 3700rpm

5.0L Very high-buck stroker

~ 4.06" offset-ground stroker crank

~ Jeep 4.2L 5.875" rods

~ Small Block Chevy UEM-KB142 hypereutectic pistons

~ 11.1:1 CR

~ Crane #751111 238/248 degree solid lifter cam

~ Ported big valve 2.02"/1.60" cylinder head

~ OEM 0.051" head gasket

~ 0.038" quench height

~ Flometrics F&B 68mm billet TB

~ 3.0" exhaust system

~ Ford 30lb/hr injectors with adjustable FPR or MAP adjuster

~ Custom PCM programming

~ 328hp @ 5250rpm, 375lbft @ 3800rpm

4.6L "poor man's" stroker

Jeep 4.2L 3.895" stroke crank

Jeep 4.2L 5.875" rods

Sealed Power 677CP +0.020" bore pistons

9.25:1 CR

Stock 4.0 HO camshaft

Ported HO 1.91"/1.50" cylinder head

Mopar/Victor 0.043" head gasket

0.088" quench height

Ford 24lb/hr injectors with stock 39psi FPR for '87-'95 engines, stock injectors with stock 49psi FPR for '96 and later engines

248hp @ 4900rpm, 303lbft @ 3500rpm

With my homebrew CAI, modified Mustang 65mm TB, TB spacer, '01 XJ intake, Borla header (modified with 3" outlet), and custom exhaust, my stroker put down the HP/TQ numbers in my sig. which are equivalent to 248hp/311lbft at the crank (slightly better than recipe numbers). As long as the outside temp. is not higher than 90*F, it'll run on 87 octane without pinging. Gas mileage is fantastic.

I'm using the stock computer with Ford racing 24lb injectors and a homebrew MAP adjuster set at 5.25v.