21xx Autolite/Motorcraft carb upgrade

Introduction The 1980 through 1988 AMC cars and trucks with the 258 engine came with the Carter BBD 2v carb. Two versions of this carb were made for six cylinder engines, feedback(computer controlled)and non feedback. The performance of this carb can be described as lackluster at best! The most common upgrade is to the Autolite/Motorcraft 2100 series(incl 2150). We'll cover a step by step upgrade in this section but before we start I'll give a brief comparison between the two carbs including what to look for in your new carb.

Carter BBD 6 cylinder feedback/non feedback 280 cfm

Autolite/Motocraft 2100 Measuring the base butterfly opening OR sometimes the number is still legible on the throttle side of the float bowl.

.98 = 190

1.01 = 240

1.02 = 245

1.08 = 287

1.14 = 300

1.21 = 351

1.23 = 356

1.33 = 424

The most common 2100/2150 in the junk yards is the 1.21, used on 302 through 390 v8 engines including 360s in the wagoneer to the end of the run in 92(actually 91).

Some 2100 swaps may be considered failures due to drivability issues. Mainly because of over carbbing some of the drivability issues with the BBD will show up in the 2100, keep in mind bigger is not always better ESPECIALLY in a relatively stock engine.

When choosing a carb be sure to get one that has the brake booster port on the rear. Older versions for cars AND trucks may not have it.

The BBD removal

http://i32.photobucket.com/albums/d45/finallyflanagan/DCFN0009.jpg

1. Gently pry the throttle rod from the ball stud on the carb

2. Place a rag beneath the fuel fitting at the carb and loosen the flare nut (carefully as there may be some pressure still in the system) Once the pressure is bled off pull the fuel line off to the side.

3. Label your electrical connections(if any) and vacuum lines. Then disconnect.

4. Finally remove the 4 retaining nuts and lift the carb off. Keep at least two of the nuts you'll need them to remove the studs later on.

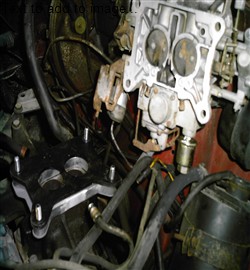

http://i32.photobucket.com/albums/d45/finallyflanagan/DCFN0001.jpg

5. Remove the phenolic spacer and the cork gasket from the manifold.

6. Clean manifold mounting surface with a wire wheel if theres a lot of buildup, otherwise use some carb cleaner then wipe.

7. Take 2 of the carb mounting nuts and jam them together on the threads of each stud and remove the studs(you can also use a pair of vice grips to just wrench them out if you don't want to keep the studs).

21xx install

!!!IMPORTANT...Test fit the adapter plate to the bottom of the carb(holding the carb upside down) The power valve screws and/or the power valve housing may interfere with some adapter plates and clearancing of the plate will be required for proper seating!!!!

1. Hold the adapter upside down and slip the supplied bolts in to the appropriate holes.

2. Use a small amount of adhesive on the supplied gasket and stick it onto the adapter, this will temporarily hold the bolts in place when you go to install the adapter to the manifold.

http://i32.photobucket.com/albums/d45/finallyflanagan/2100-10.jpg Pic of installed adapter w/o bolts installed

3. Set the adapter on the manifold and install the supplied allen head bolts tighten to no more than 7 ft lb.(some kits come with a flat head screw driver style bolt. You may want to consider replacing these with allen heads as it makes torqing the adapter down easier)

4. Install the compressed fiber insulating gasket approx 1/4 in thick.(supplied with rebuild kit for carb)YOU DO NEED THIS GASKET! This gasket ensures a complete seal across the base of the carb. The adapter does NOT seal the entire base and without this part you'll have a serious vacuum leak that will not allow tuning or driving the car!

5. Now slide the new carb on over the bolts and install the supplied washers and nuts. Torque to approx 5 ft lbs or as I did use the click elbow technique.

6. You should be able to gently bend the factory fuel line to the location of the inlet of the new carb. Install this now.

(pic to come)

7. I had to tee my pcv into the brake booster line, some carbs have this port on them and some don't. Ported vacuum is at the front (valve cover side) of the base plate and you should have enough hose to plug straight in here(pic to come). Remove the tee from the original vent line and plug the hose directly to the vent at the top of the carb.

8. Plug any unnecessary vacuum ports, and reconnect your idle solenoid(if equipped), and the electric choke wire.

http://i32.photobucket.com/albums/d45/finallyflanagan/th_DCFN0003.jpg

Note..During the rebuild I switched the choke coil housing from the carter to the autolite because I forgot to grab the pigtail from the ford. The carter has a blade terminal, the ford has a pin/weatherpack terminal.

Adjust idle screw all the way out and then run it in 2 turns for initial startup. Further adjustment can be made after warm up, Idle mixture screws should be set at approx 2.5 turns out. CHECK FOR LEAKS in the fuel lines from the carb all the way back to the pump. Safety first...

Throttle linkage

Throttle arm mod made on this swap is fairly straight forward. This is wordy but not as involved as it sounds.

1. Using a Dremel or similar rotary tool grind down the "brad" on the throttle shaft that retains the BBD throttle arm. Then carefully pry the throttle arm off.

2. With the same rotary tool grind the "brad" that retains the 21xx throttle arm to it's shaft. You should be able to overlay the AMC throttle arm on top of the 21xx arm for a test fit.

3. This step requires either a steady hand or a drill press. You will have to bore the 21xx throttle shaft and tap it for a 10/32 machine screw. Now with the machine screw and lock washer install the BBD arm over the 21xx arm.

4. Leave the throttle shaft screw barely snug and set the carb on the manifold. Pull your throttle rod up to meet the ball stud on the BBD arm. Mark the arm or tighten the shaft screw to set the new arm and remove the carb.

5. Now bore a hole through both arms at least 1/4 inch away from the throttle shaft for an 8 or 10/32 machine screw and nut. Screw the two arms together at this point and you should be ready to set the carb in it's permanent spot. ( NOTE...You will need a stronger return spring, this application used a GM style double spring from the original spring loop to a hole drilled into the 21xx arm just below the existing ball stud.)

6. After installing the carb check for any binding in the linkage. Check for full throttle when the pedal is floored(engine off of course) some adjustments may be necessary here. And check the TV rod adjustment, to get full throttle on this app. I had to raise the throttle arm "sandwich" slightly to a new secondary bolt position. This threw the adjustment for the TV rod off slightly. The service manual adjustment procedure still applies to this application.

Air filter & housing

Once you have the new carb tuned or "dialed in" satisfactorily.

I found two nice options for the air cleaner. Both are offset base assemblies that allow you to rotate them to clear possible obstructions including the hood.

http://i32.photobucket.com/albums/d45/finallyflanagan/th_DCFN0015.jpg

1. 14" HEI offset drop base free breather, jegs p/n 555-50001, It has the opening in the base offset about 2.25" from center.

http://i32.photobucket.com/albums/d45/finallyflanagan/th_DCFN0017.jpg

2. This is a closed element for a carbed Bronco 2. It too has the offset base but the snorkel has to be modified to fit the Eagle engine bay.

More to come......