Difference between revisions of "How To Upgrade Your Valve Cover"

| Line 13: | Line 13: | ||

You will want to first mark both ends of every vacuum line you want to move out of the way. I used masking tape and numbered the ends. | You will want to first mark both ends of every vacuum line you want to move out of the way. I used masking tape and numbered the ends. | ||

| − | One of your AC hoses may be in the way too. You may have to remove your compressor from the engine and move it out of the way with the hoses attached. | + | One of your AC hoses may be in the way too. You may have to remove your compressor from the engine and move it out of the way with the hoses attached. This also involves removing your [[#alternator belt]] This is a good time to replace your belts. |

Also you need to disconnect the fuel line and remove any other item which will impede the removal and installation. You will thank your self for this as the job progresses. | Also you need to disconnect the fuel line and remove any other item which will impede the removal and installation. You will thank your self for this as the job progresses. | ||

| Line 95: | Line 95: | ||

What I did was to purchase 4 short 1/4" diameter double ended studs as you will want to do this on the back one too and 4 of those round nuts (hex nuts will not clear) with the flat sides for a wrench to fit - better yet get the ones with the hex hole on top (really handy for the back one). Thoroughly degrease the holes, grind one end of the studs for the driver's side hole so they will fit snugly (you can screw the back one in) and then JB weld them in place (do not use the quick set JB weld)-- let these set up for a while until they don't wiggle. | What I did was to purchase 4 short 1/4" diameter double ended studs as you will want to do this on the back one too and 4 of those round nuts (hex nuts will not clear) with the flat sides for a wrench to fit - better yet get the ones with the hex hole on top (really handy for the back one). Thoroughly degrease the holes, grind one end of the studs for the driver's side hole so they will fit snugly (you can screw the back one in) and then JB weld them in place (do not use the quick set JB weld)-- let these set up for a while until they don't wiggle. | ||

| + | |||

| + | == Alternator Belt == | ||

| + | |||

| + | This topic is for cars with Air Conditioning. | ||

| + | |||

| + | From underneath the car, loosen the altnernator bracket lower mounting bolt (see picture). | ||

| + | |||

| + | Loosen, if equipped, the back idler attaching bolt. | ||

| + | |||

| + | Loosen the alternator bracket adjusting bolt. | ||

| + | |||

| + | Adjust alternator using a suitable pry bar. Insert pry bar through hole on bottom of bracket. | ||

| + | |||

| + | When adjusted to desired tension tighten adjusting bolt. | ||

| + | |||

| + | Check tension and adjust if needed. | ||

| + | |||

| + | Tighten adjusting bolt to 18 foot pounds; mounting bolts to 28 foot pounds and back idler to 33 foot pounds. | ||

| + | |||

| + | [[Image:acaltbelt.jpg]] | ||

Revision as of 17:44, 21 November 2005

If you have a '81 thru '86 258 with a plastic valve cover it leaks. AMC could not fix it and the only way you can is to replace with an aftermarket extruded aluminum one. Although a labor intensive upgrage it is fairly easy and should be the first thing you do for your AMC Eagle. You should plan to do this over a two or three day period, you will see why later.

An up front warning -- there was no rhyme or reason as to what holes AMC tapped for attaching replacement valve covers. Some have them all tapped while others varied. There are a couple of ways to tackle the untapped hole issue: 1) #Tapping Holes or 2) #Stud Alternative

The task at hand, getting rid of this:

There is a lot of stuff in the way of your valve cover and this is what makes it so labor intensive.

First disconnect your battery.

You will want to first mark both ends of every vacuum line you want to move out of the way. I used masking tape and numbered the ends.

One of your AC hoses may be in the way too. You may have to remove your compressor from the engine and move it out of the way with the hoses attached. This also involves removing your #alternator belt This is a good time to replace your belts.

Also you need to disconnect the fuel line and remove any other item which will impede the removal and installation. You will thank your self for this as the job progresses.

Make sure everything attached to the old cover is also removed.

Also, remove the wiper motor completely -- this is easy, four bolts and a clip that secures the motor shaft to the wiper transmission.

Lastly, tie a rope around the wire loom (you may want to remove one or two of the loom retainers on the fire wall) and carefully pull it up and out of the way as far as you can. Secure the rope, I used the back bumper.

Now you should be able to actually remove the the valve cover. It is probably attached with a bolt in the back, one in the front and 3 on the passenger side. On the driver's side you will need to remove the larger nuts and retaining washers.

Even with all that you have done to provide working room getting the old one off will take some maneuvering -- tipping it towards the passenger side to clear the rocker bridges will probably work best.

Finally it is off -- reward yourself.

Thoroughly clean the mating surface on your head to prep it for the new cover.

First determine which holes are not tapped. Probably the ones on the driver's side then decide which way you want to tackle the untapped holes; see: 1) #Tapping Holes or 2) #Stud Alternative .

Once you have completed your attachment mods you are ready to proceed with putting the new valve cover on.

The instructions that came with your new cover will probably say to attach the gasket to the cover first. DON'T DO THIS! First, put your red gasket goop on the head and put the new gasket on it, lining everything up. Finger tighten the bolts to hold it in place and leave it alone for 24 hours.

Next day. Check your work - make sure the JB weld is fully cured. Remove the bolts that held the gasket in place. Place a bead of your gasket goop on the top of the gasket.

Carefully, and this will again take some finesse place the new valve cover in place. Snug down the nuts and bolts but do not over tighten. Just tighten to the point where it is good and snug.

Walk away for 24 hours for the goop to fully cure.

Next day. Resnug your fasteners. They will probably only need a little bit of retorquing.

Replace everything else make sure it all goes back as it was before -- hence all the prep work at first.

When you are sure you have it all done, reconnect your battery and fire her up. Check for leaks. If you took your time you will probably have none.

Tapping Holes

Contributed by AMC1

Tapping the (5) 5/16” diameter holes for the cast aluminum valve cover:

Confidence factor: This was my first and successful attempt at tapping a hole...much less attempt (5) on my first try in a cylinder head. I was absolutely paranoid about breaking a tap in a hole and that paranoia will show in my procedure for tapping hole #1. All holes are the same. The procedure for subsequent holes will change only in the fact that you will be quickly become more experienced and save time without working harder. I do not want to necessarily volunteer my services to do this job since there are no guarantees in life. Having said that...if I had a friend who had to do this job...and I could see they were as apprehensive about this as I was...I would now have no problem in saying: “Bring it over and I’ll do it for you.”

Time factor: Hole #1 (passenger side front) took (3) hours. Hole #2 took (1) hour. Hole #3 took 1/2 hour and was the most difficult to do. Unless you have the automobile hood removed, you will not be working on this hole from overhead, rather on an angle. It is closer to the firewall and the wiring loom will be in the way in that it will prevent you from using 360 arcs on the tap handle... 180 degree arcs will be sufficient however. Also at that angle, your perspective of what is a perpendicular (straight) line to the hole and cylinder head may not be accurate. I was able to quickly correct myself with no damage being done because I was going slow, especially at the begining of a hole. Holes #4 and #5 took only 20 minutes each.

Taps: The instruction sheet says to use a “bottom” tap. This of course is all right if all the holes have a chamfer on the top of them. All of mine were not chamfered so I used a “taper” tap on those to begin the operation before switching over to the “bottom” tap. It does not complicate the operation and does help in attaining an original straight line into the hole.

Tools & Cost: (1) 5/16-18 hss (high speed steel) hand tap taper tap @ $2.15

(1) 5/16-18 hss with tin (titanium nitrate coating) hand tap bottom tap @

$5.80

(1) 1/4”-1/2” capacity T-handle plain tap wrench @ $3.23

shipping cost @ $5.35

Toal Cost $16.53

Procedure: Clean the hole using a cotton “Q” tip.

Insert taper tap into handle making sure it is secure and tight. Do not push it too far into the handle or it will lose it’s grip. Dip the head of the taper tap into any kind of household oil. I used clean oil however since I didn’t want to unnecessarily contanimate the tap or hole. Insert taper tap to hole and while keeping it absolutely straight to the best of your abilityturn it 1/64 - 1/32 of an inch. Back-off taper tap and wait a few seconds. Keep doing this until the tap starts to take cuts.

When the cuts start to happen and after you have backed it off...even more slowly turn the tap forward to the previous cut until you feel the place where you left off. Slowly turn it in again to the metal and continue taking 1/64 - 1/32 inch cuts. Continue backing it off after each cut. The tap may becoome loose because of all the backing-off of the tap...simply retighten it but away from the hole. At some point you will have at least one or two threads...that is all you will have needed from this taper tap. Clean the hole and threads with the Q tip but make sure the Q tip has been wiped clean or use a new one. Install bottom tap in wrench and oil the tap. Start the same procedure over again. Continue the same procedure as above.

You will now be getting a feeling of the cutting and when you meet a slightly different feeling of resistance it is time to remove the tap... clean the tap... and clean the hole with it’s new threads. I did this frequently.

The bottom tap may become loose from the hande as did the taper tap. You may not notice, but if the tap is too loose, the handle will turn but not the tap. For most of the operation, I actually held a large magnifying glass in my left hand and turned the handle containing the tap in my right hand. Do not attempt to retighten the tap to the handle while the tap is still inserted in the hole. Remove it first, always using the opportunity to clean the threads and hole.

After a few threads have been attained using the bottom tap, it is time to consider when to stop. The hole is 1/2” in depth but the bottom of the hole has a slght taper from the original drilling When you get to a depth of 3/8” the tap will meet severe resistance. I”m sure at this point many people have broken a tap. I felt that if I continued I would be using the bottom threading tap at the lower end of the hole to increase the hole diameter. For subsequent holes, I put a piece of tape at the 3/8” point on the tap to warn me that this point was approaching. I left it there and in all (5) holes I met this point of severe resistance at exactly the same 3/8” depth.

When through...I cleaned the holes with a “Q” tip...blew them out with an air hose...and took a good deep look...they looked like a real professional did the job...not an amateur like me.

Lastly I lightly oiled the bolts and installed them...they fit perfect...straight and solidly tight. No wrench was needed to install the bolts. Remember how easy they go in. Later, when installing the valve cover, they should go in just as easy. If not, you have problems with the gasket or valve cover itself. That was a different problem however.

(Note) I eventually gained alot of time by reducing the waiting time between backing-off the tap from a cut...waiting a few seconds...and advancing the tap in the hole again. I originally thought the waiting time would help cool-off the tap. In reality, since the cuts are short in distance and I was using oil and I was also removing the tap frequently enough for cleaning or re-tightening, it wasn’t getting hot enough to break. Also, if I did increase the amount of cut I was taking during the job, it probably wasn’t to more than 1/16”to 3/32” total. Don’t get overconfident and go too fast.

Have fun...I did (starting on hole #2) AMC1 <Bob Lavine>

Stud Alternative

What I did was to purchase 4 short 1/4" diameter double ended studs as you will want to do this on the back one too and 4 of those round nuts (hex nuts will not clear) with the flat sides for a wrench to fit - better yet get the ones with the hex hole on top (really handy for the back one). Thoroughly degrease the holes, grind one end of the studs for the driver's side hole so they will fit snugly (you can screw the back one in) and then JB weld them in place (do not use the quick set JB weld)-- let these set up for a while until they don't wiggle.

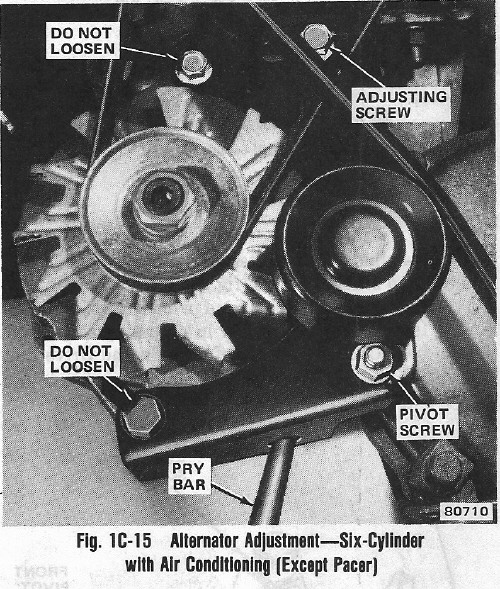

Alternator Belt

This topic is for cars with Air Conditioning.

From underneath the car, loosen the altnernator bracket lower mounting bolt (see picture).

Loosen, if equipped, the back idler attaching bolt.

Loosen the alternator bracket adjusting bolt.

Adjust alternator using a suitable pry bar. Insert pry bar through hole on bottom of bracket.

When adjusted to desired tension tighten adjusting bolt.

Check tension and adjust if needed.

Tighten adjusting bolt to 18 foot pounds; mounting bolts to 28 foot pounds and back idler to 33 foot pounds.